|

|

As lifestyles undergo dramatic change with the advent of the advanced information-oriented society, diets are also becoming highly diversified.

Founded in the 10th year of Meiji (1877), our company has devoted itself to noodle making and has continued to grow in spite of great difficulties thanks to the united efforts of our employees cherishing our motto of "Heartfelt product making."

In these turbulent times, we hold a broad perspective and maintain a flexible setup for responding to diverse changes and needs, and we are committed to realizing further advances while placing emphasis on "Contact with flavor."

As well as addressing the domestic and overseas markets, we aim to progress as a socially responsible enterprise that cherishes "Heart-to-heart connections."

Moving forward, I look forward to receiving your ongoing support and instruction.

| 1954, June | Yoshiaki Shibayama, the previous president, inherited the family business comprising a small plant conducting integrated wheat collection, flour making and noodle manufacture, and made this the headquarters of a limited company with capital of 500,000 yen. Around this time, the company announced its policy of focusing only on "Kishimen" noodles and started selling packaged Kishimen in boxes all over Japan based on a sale agreement with Meitetsu Department Stores and others. |

|

| 1973, March | Purchasing a site of 3,000㎡ in Konan City, the company constructed a three-story modern reinforced-concrete factory and packaging plant, office block and dormitory and established the basic production setup for 50,000 meals per day. Also, it upgraded the former Konan plant and expanded the head office. |

|

| 1977, May | A new noodle manufacturing and noodle boiling factory was constructed on the site of the Konan plant. |

|

| 1977, September | Yorimitsu Wakita was appointed as representative director. |

|

| 1977, October | The head office was transferred to inside the plant. |

|

| 1983, December | Kishimentei Limited Company was established, and the restaurant division was separated as an independent entity. |

|

| 1988, April | The Ichinomiya plant was constructed in Ichinomiya City, Aichi Prefecture. A raw noodle production setup with capacity of 20,000 meals per day was established. |

|

| 1992, January | As a dedicated boiled noodle facility, the Ichinomiya No. 1 plant was established with production capacity of 40,000 meals per day. The former Ichinomiya plant (raw noodle plant) became the Ichinomiya No. 2 plant. The product management center (distribution center) was newly established inside the No. 1 plant, and a warehouse with capacity of 800 pallets was established. |

|

| 1992, September | Additional hand-prepared noodles equipment was installed in the Konan plant. Capacity for making 6,000 meals per day on two lines was secured. |

|

| 1994, January | A new automatic warehouse with capacity of 800 pallets was installed on the site of the No. 1 plant. This rationalized and speeded up the receiving and shipping work. |

|

| 1997, October | The Konan plant was expanded and renewed as two totally automated dried noodle manufacturing lines, raising production capacity to 100,000 meals per day. At the same time, an additional packaging line was installed. |

|

| 2001, August | A fully automated highly-hydrated raw noodle plant was newly established in the Ichinomiya plant, thereby securing production capacity of 30,000 meals per day. A three-pronged setup for dried noodles, boiled noodles, and raw noodles was established here. |

|

| 2002, April | Office automation was completed with the introduction of PCs. In addition to rationalizing clerical work, this enabled each plant, the product management center and headquarters to be connected online. |

|

| 2003, September | Takayoshi Wakita was appointed as representative managing director. |

|

| 2005, March | Additional hand-prepared noodles equipment was installed in the Konan plant. Capacity for making 9,000 meals per day was secured. |

|

| 2006, May | X-ray inspection equipment was introduced to the packaging lines at the Ichinomiya and Konan plants. |

|

| 2011, May | ISO9001: 2008 certification was acquired by the headquarters, Ichinomiya and Konan plants. |

|

| 2013, March | Solar power generating equipment with capacity of 49kW was installed at the Konan plant. |

|

| 2014, March | Solar power generating equipment with capacity of 49kW was installed at the Ichinomiya plant. |

|

| 2018, April | Migrated from ISO9001 2008 version to 2015 version. |

|

Commitments to Our Customers

- We will deliver products that give "satisfaction with a smile" to all our customers.

- We will properly adhere to our customers' requests and keep our commitments to them while upholding the law.

- We will build a system for managing and maintaining the quality of products and work, and give this system value through constantly striving for improvement without complacency.

April 1, 2010

Nagoya Kishimentei Co., Ltd.

Representative Director & President : Takayoshi Wakita

What is Kishimen?

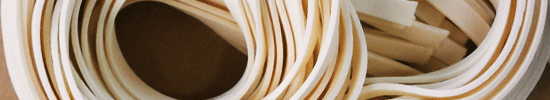

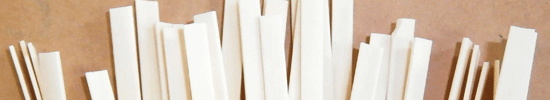

- Kishimen noodles are wider than conventional noodles.

- Dried noodle quality standards require that noodles are no less than 4.5mm wide, no greater than 2.0mm thick, and are made from wheat flour.

- They are usually eaten with soy-based sauce flavored with bonito and kelp stock and topped with kamaboko fish paste, spinach and bonito shavings.

- Flat noodles taste best when mixed and eaten with soup.

Origins of Kishimen

- Blessed with the clear waters of Kiso River and ideal climate conditions, Owari Plain has long been a noodle producing area. Among the local products, Kishimen noodles have widespread popularity among food aficionados throughout Japan as a representative product of Owari Nagoya.

- There are numerous stories about the origins of Kishimen. It is said to have originated from flat noodles that were served with pheasant ("Kiji" in Japanese) meat for a lord in Nagoya, thus giving the name "Kijimen;"another story is that it derived from "Kishumen" from the Kishu area; and there is another story that the vassals of Takeda Shingen during the Warring States Period introduced "Himokawa" and "Hoto" flat noodles to Owari from the Kanto region.

- The existence of these different stories, without any one established theory, adds to the mysterious appeal of "Nagoya Kishimen" noodles.

- Following repeated research aimed at serving delicious yet inexpensive Kishimen noodles while adhering to tradition, Nagoya Kishimentei has finally established a vaunted manufacturing method and flavor that is in no way inferior to hand-made noodles.

- This Kishimen may be called an entirely natural food that is finished with completely "old-style" color and flavoring.

|

|

商品お届けの際、運送会社(ゆうパック/ヤマト運輸)のドライバーへ現金にてお支払いください。

商品お届けの際、運送会社(ゆうパック/ヤマト運輸)のドライバーへ現金にてお支払いください。