Manufacturing Processes:Boiled Noodles

1. Mixing

4. Quantity adjustment and cutting

7. Packaging

- 1

- Mixing

- Put the raw materials (flour) into a mixer from the silo and mix them together with salt water.

- 2

- Vacuum

- Make a noodle sheet by vacuum noodle sheet machine.

- 3

- Rolling

- Pass through rollers in order to obtain the fixed thickness.

- 4

- Quantity adjustment and cutting

- Cut the noodle sheet into the fixed width and length.

- 5

- Boiling

- Boil with boiling water in a boiling tank.

- 6

- Cooling and pH adjustment

- Cool using cold water with the pH level adjusted in a pH tank.

- 7

- Packaging

- Put the noodles into bags using a packaging machine.

- 8

- Heat sterilization

- Conduct heat sterilization by steam in a sterilization chamber at 90~95℃ for 35~45 minutes.

- 9

- Cooling

- Cool by means of cold air in a cooling chamber.

- 10

- Weighing and inspection

- Weigh in a weight checker, and check for foreign objects using a metal detector.

- 11

- Packaging and packing

- Package in the prescribed bags by packaging machine, and pack into boxes.

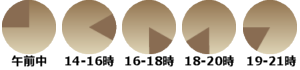

商品お届けの際、運送会社(ゆうパック/ヤマト運輸)のドライバーへ現金にてお支払いください。

商品お届けの際、運送会社(ゆうパック/ヤマト運輸)のドライバーへ現金にてお支払いください。